Engine mounts are crucial but often overlooked part of your boat. Ben Sutcliffe-Davies explains how often you should replace them, and what happens when they break down and fail.

Marine engine mounts are designed to isolate engine vibration noise from the boat’s structure. They’re susceptible to diesel and water leaks, should be checked regularly, and replaced every 10 years, advises marine surveyor Ben Sutcliffe-Davies.

“So many people forget the engine is secured to the boat and the transmission works by pushing the boat along on the engine mounts,” he says.

“When you open the throttle, all the loading to push the hull is pushed through the mount as the propeller tries to pull the engine backwards.”

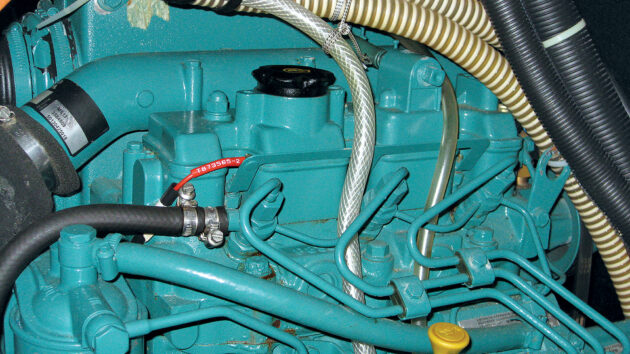

In the example pictured, the mount came from a 400hp inboard engine.

The fault wasn’t obvious in-situ, but alarm bells rang for Ben when he put a pry bar underneath and rocked it – something he does in most surveys. A tiny amount of movement is acceptable, but anything more and there could be problems.

Damaged engine mounts are just one of many things a marine surveyor encounters. Photo: Ali Wood.

He asked the boatyard to investigate further.

A staff member called him back to inform him that every engine mount had failed. They were removed from the boat, and when Sutcliffe-Davies inspected one, he saw it had broken in two. The rubber seal had completely come apart from the steel.

Reasons for engine mount failure

This process, known as devulcanization, breaks down the mechanical properties of rubber.

What was originally hard and durable is now back to its raw state, because of heat exposure and being mixed with sulphur from the diesel. The bond is broken. In fact, it’s the same process used to recycle tyres… though you don’t want it happening in the engine room!

The rubber component has completely come apart from the steel. Photo: Ali Wood.

Because of the weight on the mount, which is secured by bolts, this isn’t something you can see in situ. However, the movement is a giveaway.

How often should you change your engine mounts?

“We recommend you change engine mounts every 10 years,” says Sutcliffe-Davies. “Ideally change the whole lot, but if you find failure on just one, at least change the pair on that parallel, whether that’s two aft or two forward.”

Symptoms of bad engine mounts

The other thing you should do – as well as checking for movement – is check where the engine feet sit on the mount.

“The leverage here is phenomenal,” Sutcliffe-Davies points out. “You can see from the corrosion here that it’s been set up right at the top. The engine feet should always be a third or at most a half away from the shoulder. If you need to build them up use packers – don’t increase leverage on the thread bar.”

Other risks facing your engine mounts

Additionally, if you’ve had a rope around the prop, check your engine mounts. They may have failed from the additional pull on the engine. It’s a quick job, but one that could save you a lot of money.

A rope around the prop could lead to engine mount damage. Photo: Jim Gibson / MBY.

Watch this video at pbo.co.uk/engine_mounts. For more fascinating survey finds see Ben Sutcliffe-Davies’s YouTube channel, the Surveyor’s Notebook, or visit www.bensutcliffemarine.co.uk.

How to make your engine quieter

On a quest for quiet, Chris Mardon replaces the engine mounts on his Dufour 40.

Spook is a 2004 Dufour 40. Photo: Chris Mardon.

Manufacturers all too often install engines on mounts that do not isolate noise as well as they could. My mounts were 13 years old and I wanted to make my engine quieter so I took the opportunity to replace them.

The rubber bonded within engine mounts comes in varying degrees of hardness. Softer rubber gives better isolation but it has less load support and may allow more engine movement, so you need to check the mount supplier’s maximum load.

Anti-vibration (AV) rubber hardness is expressed in ‘shore’ units from 30 at the soft end to 75 shore at the hard end.

Engine weight is usually specified as ‘dry weight’ so I added the weight of engine oil, gearbox oil and coolant (another 12kg to the dry weight of my 40hp engine).

Engine/gearbox assemblies with shaft drives are usually supported on four AV mounts and saildrives are usually on three. Don’t forget that a shaft drive engine/gearbox should be realigned with its prop shaft after new AV mounts have been fitted.

The Volvo Penta Saildrive unit on Spook. Photo: Chris Mardon.

Alignment requires a degree of skill. Saildrive units will not need realignment provided the new mounts are the same height as the old ones.

Looking at the side-on drawing of my engine enabled me to make a fair estimate of the position of its centre of gravity (CG). The CG is the point of balance between the front and back of the assembly.

On a cast iron engine block this would be about halfway between the front and back of the block, but will move towards additional weights such as the flywheel and the gearbox.

I didn’t have to be dead accurate as I was deliberately selecting AV mounts capable of carrying about 10% more than my engine’s maximum overall weight.

Bear in mind that the more approximate the estimate of the position of the CG, the greater the safety margin you’ll need.

Chris sent photos to online suppliers to help identify his mounts. Photo: Chris Mardon.

Lessons

Supplier specifications showed the maximum load that each shore number was designed to take. My original (45 shore) mounts could support 150kg, nearly double their actual load. No wonder they transmitted so much vibration into the boat.

The weight on my front mounts (82kg) was 78% of the maximum load of 105kg for my chosen (35 shore) mounts – a reasonable safety margin.

The new mounts were easy to fit thanks to the Dufour 40’s excellent engine access.

But how much difference did it make to my boat?

The engine mount in situ. Photo: Chris Mardon.

I only changed my front two mounts as the rear saildrive mount is on the centre line of the engine/gearbox assembly and would have had little effect on the rocking motion of the engine.

With the old (45 shore) mounts we used to suffer from some floor panels, doors and oven parts rattling and the whole boat was excessively noisy down below.

The new mounts seem to have completely eliminated these vibrations and those noisy rattles have disappeared. The engine also sounds more hidden away and is less intrusive.

Spook’s engine is a 217kg Volvo Penta MD2040 with a ZF gearbox. Photo: Chris Mardon.

It’s been a good investment for £95 (inc delivery). You can pay a lot more but I couldn’t find any advantages in the higher priced mounts. Although my boat is a sailing yacht, this modification can equally apply to many inboard engined power boats.

Boat engine mount replacement: step by step guide

Mike Reynolds shares the lessons he learned about undertaking a boat engine mount replacement

How to service a marine diesel engine in 12 simple steps

It was time to service the marine diesel engine on our Maxi 84 cruiser. Knowing how to diagnose and fix…

Want to read more articles like this?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price.

Print and digital editions are available through Magazines Direct – where you can also find the latest deals.

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

-

-

-

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial, in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

-

-

Follow us on Facebook, Instagram, TikTok and Twitter