Zoran Glozinic builds a specialised wire rigging tool

This rigging vice is simple to make and keep in your tool box on your yacht.

It’ll make your life much easier in case you need to mend a broken lifeline, stay or shroud on your yacht. And it’ll be invaluable if you ever decide to replace some or all of your wire standing rigging.

Even if you don’t know how to make a proper splice in multi-strand wire, this vice can make installing a temporary bulldog wire clip much easier, and the resulting job will be much better with wire much tighter around the thimble/eye.

Tools like this are fairly expensive, and buying one doesn’t make much sense if you’re not going to use it often.

You can make one for almost nothing – you just need some hard wood and a few machine screws. And of course, a couple of hours of your time!

Cardboard templates for the rigging vice were traced and cut out. Credit: Zoran Glozinic

The main idea here is to hold the wire tight in place without moving around a metal or plastic thimble or eye, while you work to secure the wire around the thimble.

The preferred method would be to use splicing, but you can use other methods as well – bulldog wire clips or Nicopress sleeves, for example.

If you’re a novice in this kind of work, it’s always recommended to consult with a professional rigger, especially if you’re doing something on standing rigging.

The reason I made a rigging vice was that I finally decided to replace the standing rigging on my small yacht.

I wanted it to accommodate a few different sizes of wire and thimble combinations. The three sizes I selected then dictated the dimensions of the vice.

All parts cut and pronged T-nuts installed. Credit: Zoran Gloznic

On my yacht, most of the standing rigging is wire 5/32in diameter, but I do have some 3/16in and 1/8in as well, so my vice was designed with these three sizes in mind.

I’ve seen many variations of this device on the internet or in various boat rigging books, but the most helpful was a drawing showing an old-fashioned vice in the book The Complete Rigger’s Apprentice by Brion Toss.

That drawing made me realise that I could make the vice from wood – no welding required!

After I made a sketch, I drew all the shapes on graph paper before glueing them to thick cardboard and cutting them out. I wanted to test how the ‘arms’ and ‘head’ fit around all three sizes of thimbles I was planning to use.

Parts ready for mounting on the base. Credit: Zoran Glozinic

Everything looked okay, so I traced the shapes to a piece of 1in thick oak.

After cutting the parts, I drilled all holes and installed three-pronged T-nuts.

I used Allen head machine screws to move/adjust the arms and head of the rigging vice.

On the screw used for moving the head, I filed off a portion of the threads so the end of the screw was free to turn in the head without the threads grabbing the wood. A piece of particleboard was used as a base to mount everything.

After marking the positions of the arms and block, I drilled all holes and mounted everything. I used locknuts everywhere.

The screws holding the arms should not be too tight so they can move freely.

The vice is made of hardwood, nuts, bolts and washers, pronged T-nuts and hex screws. Credit: Zoran Glozinic

I mounted a wooden cleat to the base’s underside so I could secure the base in the vice on my worktable in a position so that when you’re working, the ends of the wire are out in the open.

As this little tool will most likely live on the boat, it’s a good idea to apply some kind of protective finish.

I just coated everything with teak oil, including the screws and I keep it in a stout plastic bag.

How I made a specialist tool to repair my dinghy

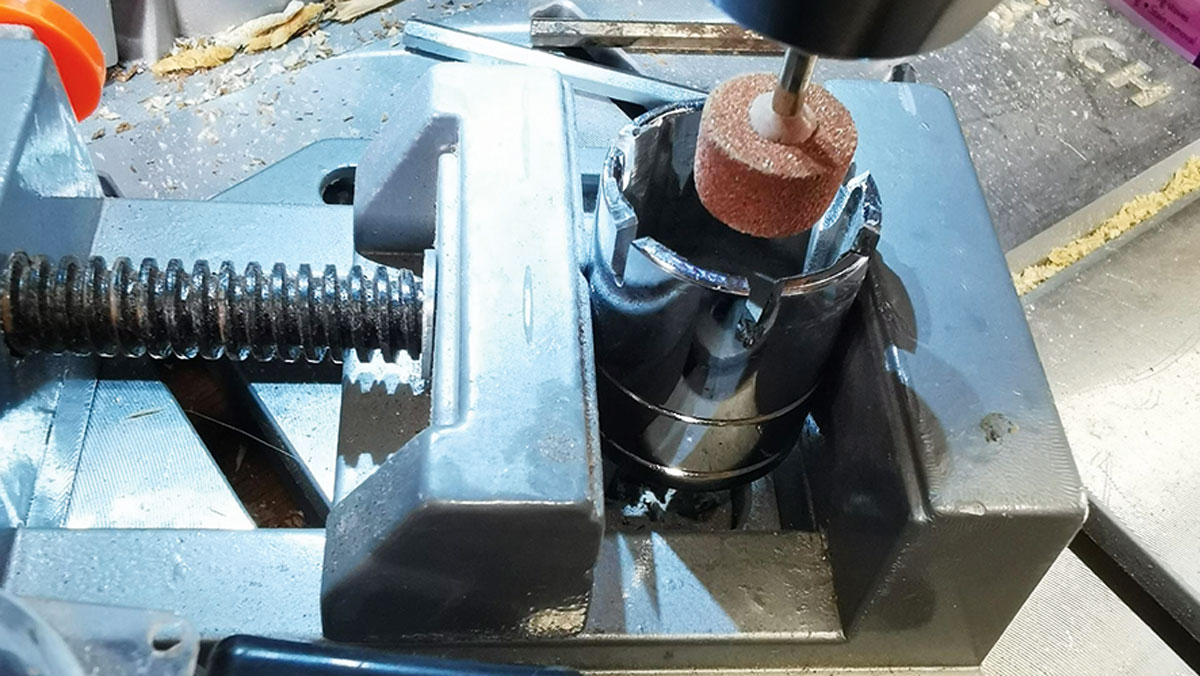

Paul Diamond creates a specialised valve removal tool from a socket spanner in order to repair his inflatable tender

Why you should consider the weight of boat tools

Minimise the need for weighty tools on board by swapping metal parts with wood and rope, and muffling those you…

Refining rigging and improving performance

Sometimes you have to be cruel to be kind. When, back in 2014, I saw the mainsail on Peter Kewish’s…

Rigging setup: Turning round a yacht’s performance

Little old boats can offer enormous fun for your money, but they often require some tweaking in order to be…

Want to read more articles like this?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price.

Print and digital editions are available through Magazines Direct – where you can also find the latest deals.

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

-

-

-

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial, in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

-

-

Follow us on Facebook, Instagram, TikTok and Twitter