Do you know the difference between a sudden fracture and a fatigue fracture? Understanding the characteristic 'beach marks' is the key to preventing catastrophic failure on your boat, says Vyv Cox

There is a great deal of confusion in yacht owners’ minds about the topic of metal fatigue.

Metal fatigue suffers on account of its name, which many people associate with tiredness in humans.

In fact, fatigue in metal components occurs when a crack grows through them, until finally the force being transmitted exceeds the strength of the remaining material and it breaks.

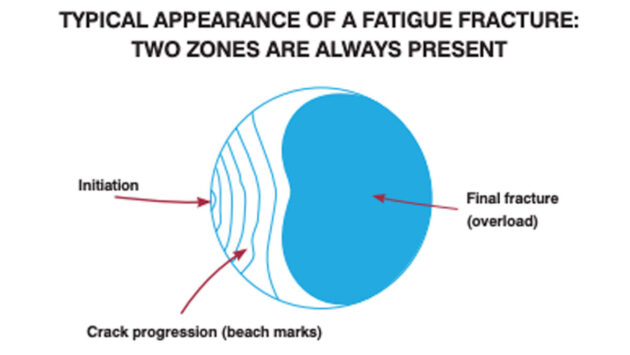

The consequence of this mechanism is that fatigue fractures always have a characteristic two-zone appearance – the part where the crack was propagating and the final fracture.

The diagram above shows a typical appearance. A simple fatigue crack is initiated at a single point. The crack grows through the metal from that point in the way that ripples spread from a pebble thrown into a pond.

This can result in a very characteristic appearance, known as beach marks, particularly if the crack stops and starts periodically as the stress varies.

Sometimes fatigue cracks have multiple origins, such as along sharp changes in section.

Why does metal fatigue occur?

Fatigue is the result of cyclic stress, perhaps the most common example being the bending of a piece of wire backwards and forwards until it breaks.

In yacht engineering, it is very common where components like bolts and rigging are insufficiently tight, allowing cyclic movement to apply stresses to a point where they are maximised, such as changes in section, swaged fittings, holes and various others.

It has been common in engine mountings, but modern versions are made stronger and less flexible.

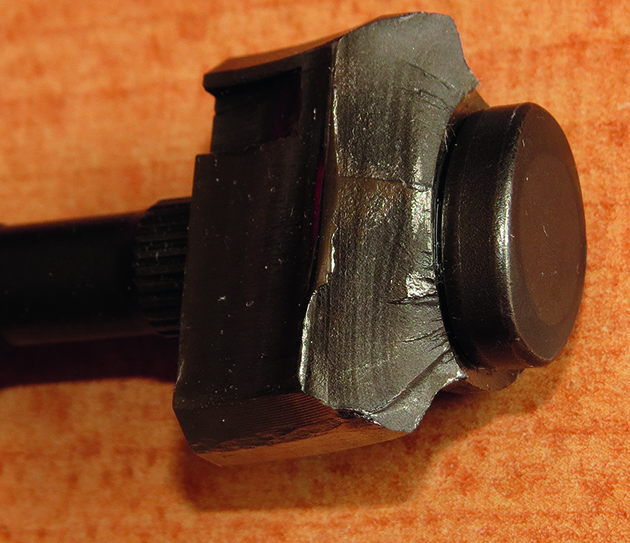

Metal fatigue: failed connecting rod

The photo below shows a failed connecting rod from a Volvo Penta D2-40 engine, where the fatigue crack was initiated along a line near the bolt head rather than at a single point.

The bolt was loose, resulting in the transfer of stress to the connecting rod.

Propagation took place towards the camera, producing beach marks and some polishing where the two faces rubbed together before final fracture.

The failed connecting rod from a Volvo Penta D2-40 engine

A description of fatigue failure often expressed is that the failure was ‘sudden’, ‘out of the blue’ or ‘with no warning’.

The reality is that the crack may have been growing for months or even years, failure taking place when the stress in the remaining part of the metal exceeded its strength.

The well-publicised loss of the yacht Harrier of Down, following the fracture of a heavy rudder stock, was almost certainly an example of this.

The main difference between the diagram and real fractures in engineering components is that the final fracture area is usually quite small.

Safety factors are such that most components are capable of carrying far greater forces than they see in service.

The final fracture area in the connecting rod photograph is the bright area at the extreme left, along with the ‘shear lip’ where the metal has been pulled outwards.

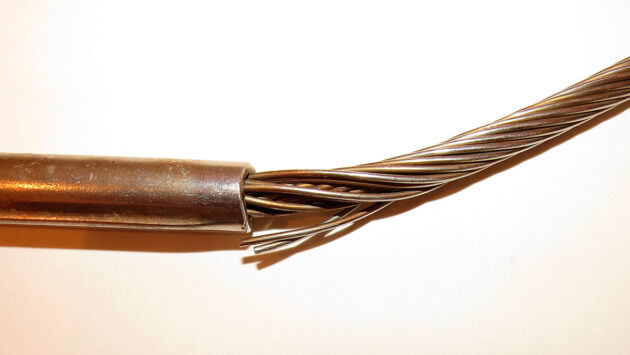

Failed shroud due to metal fatigue

I was sent a failed shroud to examine (main opening photo). It was known that the rig had been very slack for some time, with the result that a couple of shroud wires had fractured and were protruding from the swaged fitting.

I examined the wire ends with a microscope and could identify beach marks on one and polishing on the other, both indicating fatigue. Credit: Vyv Cox

I examined the wire ends with a microscope and could identify beach marks on one and polishing on the other, both indicating fatigue.

I slit the swaged fitting open to reveal that several more wires were fractured inside. Credit: Vyv Cox

Finally, I slit the swaged fitting open to reveal that several more wires were fractured inside. This owner was fortunate that his mast and rig remained in place, as no doubt the other wires were also fatigued but not yet fractured.

Bending stresses

A couple of years ago, we were berthed adjacent to a very well-found Italian boat fitted out for long-distance cruising.

We met the owner and enjoyed an evening with him and his crew. A few days later, we had moved on and met him again, in very different circumstances.

On passage between islands, a shroud had failed, his mast had gone over the side, and his cruise had been ruined.

I diagnosed the shroud failure on this long-distance cruiser as the result of metal fatigue.

The mast had gone over the side, and the boat owner’s cruise was ruined as a result. Credit: Vyv Cox

I inspected the shroud tang that had failed and found fatigue to be the cause.

The fitting had been riveted directly to the mast without toggles, allowing bending stresses to act directly upon it.

The failed shroud tang from the mast of the boat pictured above. The crack initiated along the whole width at the lower edge of the tang. Credit: Vyv Cox

The crack initiated along the whole width of the tang at the lower edge in the photograph, forming beach marks as it propagated and finally failed along the top edge.

Carry out regular checks of at-risk components

So far as prevention is concerned, the yacht owner should ensure that the rig of his boat is kept tight, make regular checks of components known to be at risk, such as all wires, engine mountings, coupling bolts, forestay attachments and suchlike.

Of particular importance, it is essential that all standing rigging is fitted with toggles that prevent the direct application of stresses to the mast or fittings.

This photograph shows a typical intergranular fracture with no sign of a two-zone appearance. Credit: Vyv Cox

Check all aluminium components. The fracture face photograph (above) shows a typical intergranular fracture with no sign of a two-zone appearance.

Aluminium readily fails in fatigue, often displaying beautiful beach marks, but it does not normally fail in a brittle mode unless there are environmental factors.

Corrosive media can penetrate the metal along grain boundaries, resulting in a brittle appearance on fracture.

Metal fatigue in rig components: crack detection by dye penetrant

Metallurgist Vyv Cox shows how strongly-coloured dyes can be used to reveal fatigue cracks in rig components

What can I use to lubricate metal?

Colin Staples wants to know what is the best product to lubricate metal to keep his stiffened outboard bracket moving…

Boat anodes: a practical guide for sailors

Metallurgist Vyv Cox’s guide to anodes, explaining how they work, debunking the myths and showing ways of improving performance

Is it a good idea to weld anchor chain to lengthen it?

Practical Boat Owner reader Tom Fox ponders if a qualified welder could weld anchor chain. Metallurgist Vyv Cox explains what…

Want to read more articles like Understanding metal fatigue: What causes rigging and engine failures?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price.

Print and digital editions are available through Magazines Direct – where you can also find the latest deals.

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

-

-

-

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial, in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

-

-

Follow us on Facebook, Instagram, TikTok and Twitter